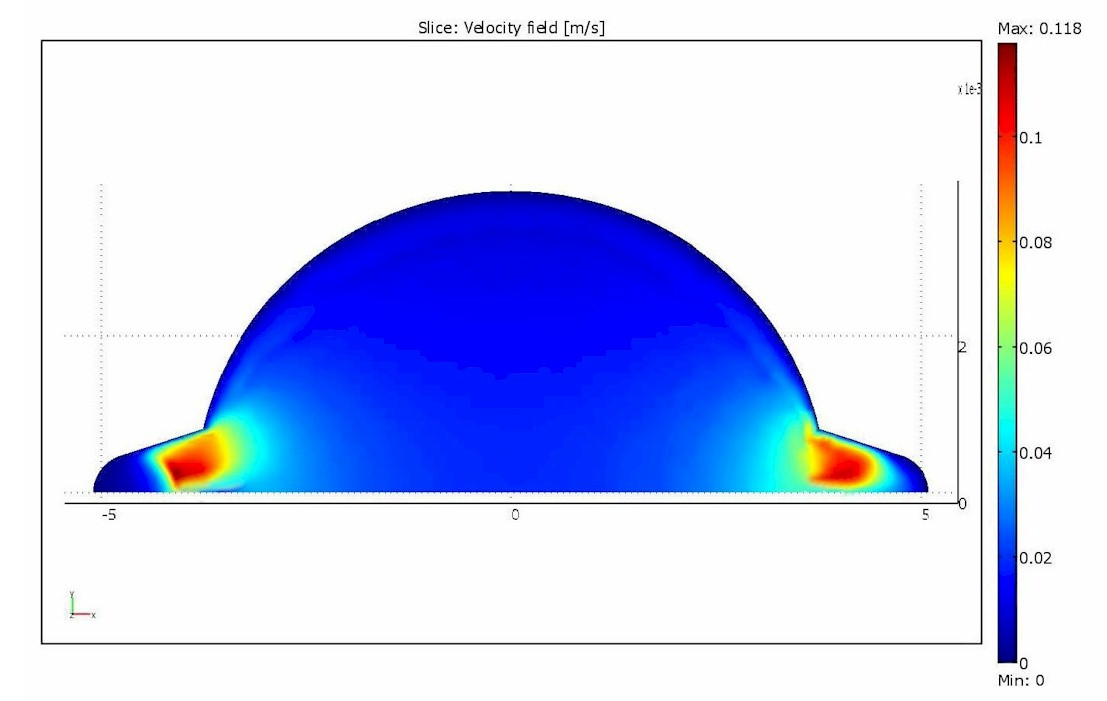

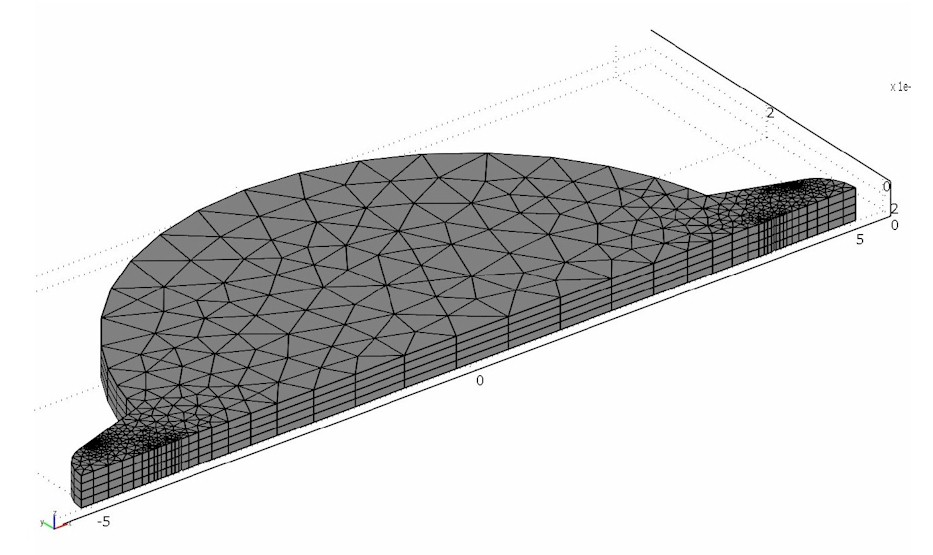

Of central interest for reproducible and more meaningful in vitro diagnostics is the short distance to in-vivo conditions. A patented sample carrier (multi-well plate) with integrated microfluidic and sensors ensures a regulated and reproducible exchange of culture media, the removal of metabolites and a precisely metered addition of agents. The sample carrier is used as an interface between a liquid handling system, such as a pipetting robot, and the fluidic directly at the cell culture. The microfluidic of this integrated cell-chip system has a crucial influence on the sensitivity and responsiveness of cell-modulated measurements. The adjustable volume of the cell culture chamber, but also the flow within, is of particular importance. These parameters determine how fast an analyte can be detected by the sensors.

The technological edge:

• Realistic simulation of tissue situation

• Simultaneous and dynamic tracking

• Real-time detection of pH and pO2 value (metabolism)

• Real-time impedance measurement

• Long-term cell monitoring (Regeneration effects can be detected)

• Microscopic examinations are possible

• Compatible with all common liquid handling systems

• Simultaneous analysis of up to 24 or 48 cell samples

Liquid Handling

The patented multi-well plate ensures a minimal invasive parameter recording with simultaneous media and drug supply.

Liquid handling is an important part of automation for High-Content Screening especially as the demand for standardization and efficiency increases. With cell based assays, automation is being used to seed, wash, and assay plates faster and with less variation than customary manual methods. Cytophorics uses a multi-well plate with up to 24 micro fluidic reaction chambers in parallel.

The liquid handling of the Cytophorics system demonstrate that complex, multiple step cell based assays can be optimized in a fully automated system. Our results demonstrate that, with assay optimization, multiple step cell based assays can be fully automated to yield highly reproducible results.

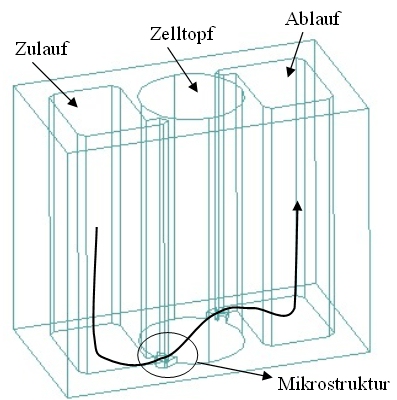

The fluid system consists of a reaction vessel with the cells, which is connected via micro-structured channels to an inlet and outlet container (see illustration). The sensors (sensor-chip) are at the bottom of the reaction chamber. From above an accurately fitting plunger is introduced to limit a defined measurement volume. The three-chamber system can be considered as a system of communicating pipes, wherein the two outer containers are seen as an open and the reaction vessel as a closed system.